Medical Equipment Repair Jobs - What Skills Are Required?

Do you find yourself looking for a career you know will enjoy and have a passion for? Before collage it is not easy to know what your career path will be. In fact, according to Forbes Magazine only 27% of college graduates are working in a job that even relates to what they majored in. If you are considering Bio-Medical engineering or medical equipment repair, this article my help you discern if it is a good career path for you to follow.

The first question is do you have an aptitude for technical skills, are you looking for hands on working experiences, do you enjoy the challenge of troubleshooting, can you work under time constraints? These are all questions you may need to ask yourself when considering medical equipment repair as a career choice.

The Market Perspective:

Medical equipment repair is a growing industry. The market is demanding more and more skilled technicians, for equipment that we getting more and more complex. Healthcare overall is growing and the Bureau of Labor projects job growth in this market till 2022.

Interested in learning more about what it takes to do medical equipment repair? Learn about the experience it takes to get started in the industry.

Experience Needed to Repair Medical Equipment:

Repairing medical equipment is a technical skill, you have to have some electrical and mechanical experience, be able to work with your hands but also be able to communicate with management, and have an aptitude for hands on labor.

Below you will find the common traits needed to become a successful medical equipment repair technician.

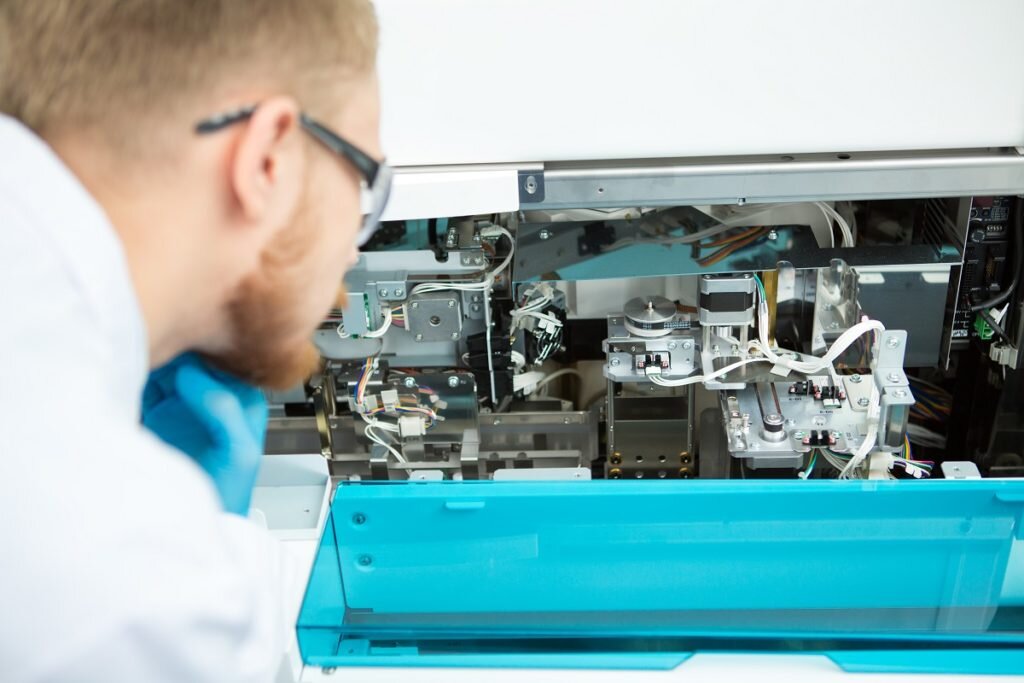

1) Hands On Skills:

Repairing medical equipment calls for a lot of hands on time with diverse equipment. In one day you can be expected to disassemble and reassemble many various types of machinery. Being familiar with tools and knowing how to use them is a necessity.

2) Communication Skills:

This is a skill that is often overlooked but very needed when it comes to medical equipment repair. Great technicians have the ability communicate both with management and the medical teams they are helping. They also need to have the ability to communicate the problems to the equipment manufacturers in order to identify the steps and parts that may be needed to rectify them.

Once the problem is identified the technician also needs to then be able to convey and coordinate the timeframe of which the repair will be completed to both the caregiver and his/her manager. Communication is also needed in order to be able to convey what the problems are and how it occurred.

3) Understanding Service manuals and Schematics:

To become a successful technician you need to be able to read a schematic diagram. This is very important in trouble shooting equipment. Service manuals overview the equipment’s theory of operation and offer troubleshooting advice. To be able to read and understand service manuals and wiring schematics, is critical, especially with the more modern sophisticated equipment.

4) Have a knowledge of electricity:

Almost medical equipment has electrical elements. You don’t need an electrician’s license to work with medical machines but you will need to have an understanding of how electricity works and how it relates to the machines you will working on.

Working with a millimeter in an everyday occurrence for biomedical technicians.

There are some basic things like the difference between A/C current and D/C current. How to read voltages and continuity is necessary for finding faulty connections.

5) Good at working under time constraints:

There is often a limited amount of time the machine is available for service. Biomedical Technicians are often expected to work on items between patients. Good technicians can work on equipment quickly under time sensitive situations.

Working under pressure is not easy and often when mistakes happen being able to maintain concentration and composure while assuring the practitioner you are doing everything you can to get his/her equipment back up and running is a day in the life of a medical equipment repair tech.

6) Documentation

After a repair is completed it needs to be properly documented. This is a service report that is filled out by the tech which states the date and time spent on the equipment, the equipment information make model and serial number, the problem that was occurring, what rectified the problem and what parts were replaced.

Having this documentation is not only necessary for getting compensated for the work also to keep a history of each item that was serviced in view of possible future malfunctions with the equipment.

Is Medical Equipment Repair For You?

If you feel you have the skill sets to succeed, aptitude towards hands on work, deliver quality service in multiple situations, and work well under pressure, document and communicate effectively, repairing medical equipment might be the right fit for you.